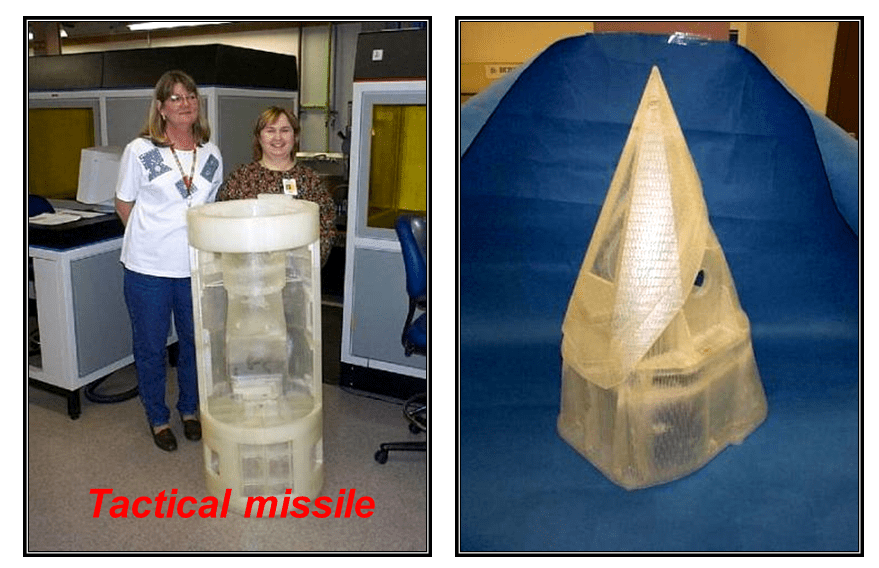

3D bugu yana da fa'ida a bayyane ta sauri a cikin ?ananan samarwa da ha?aka wasu nau'ikan ayyuka, kamar motoci, sararin samaniya, jirgin sama, soja, jirgin ?asa, babur, jirgi, kayan injin, famfo ruwa, yumbu, da sauransu.

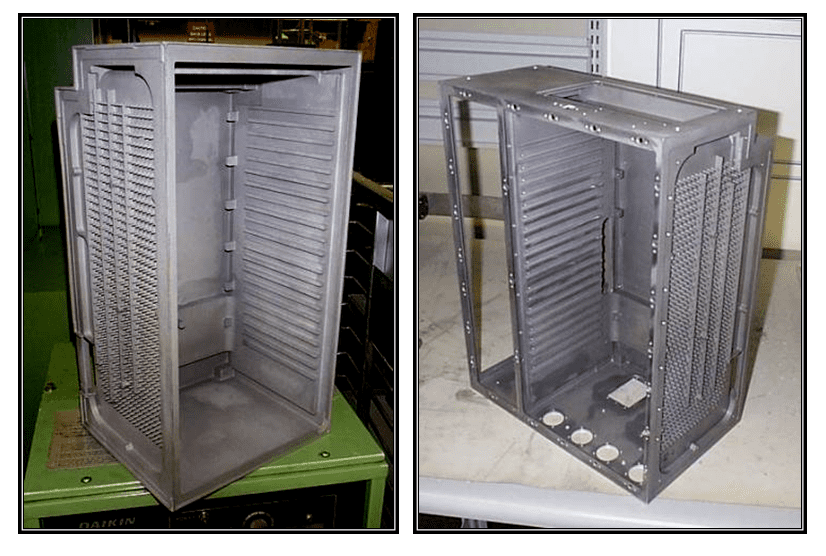

Ana iya samar da samfuran simintin gargajiya iri-iri wa?anda ke da wahalar samarwa ta hanyar bugu na 3D kamar ruwan injin turbine 0.5mm, sassa daban-daban na mai sanyaya na ciki, da simintin simintin gyare-gyare daban-daban.

Don sassa na fasaha, ana iya amfani da nau'ikan ?ira iri-iri don samarwa da yawa.

3D bugu yana ha?aka masana'antar simintin gyare-gyare

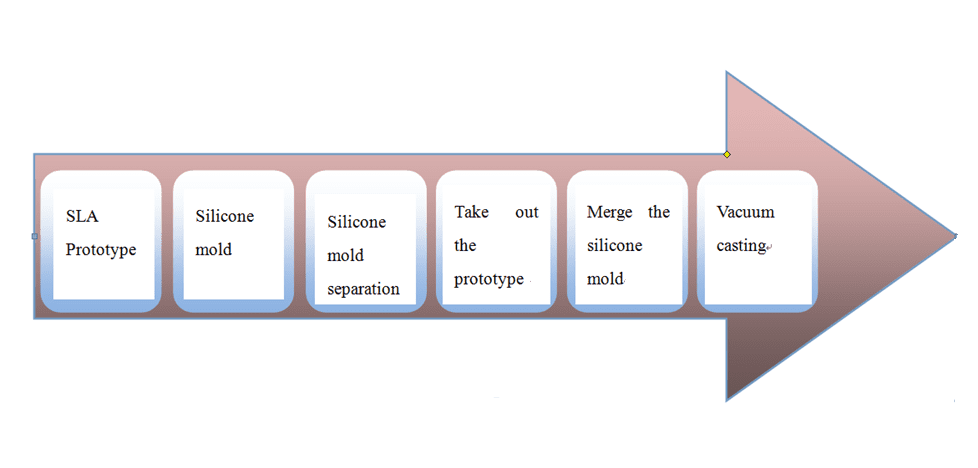

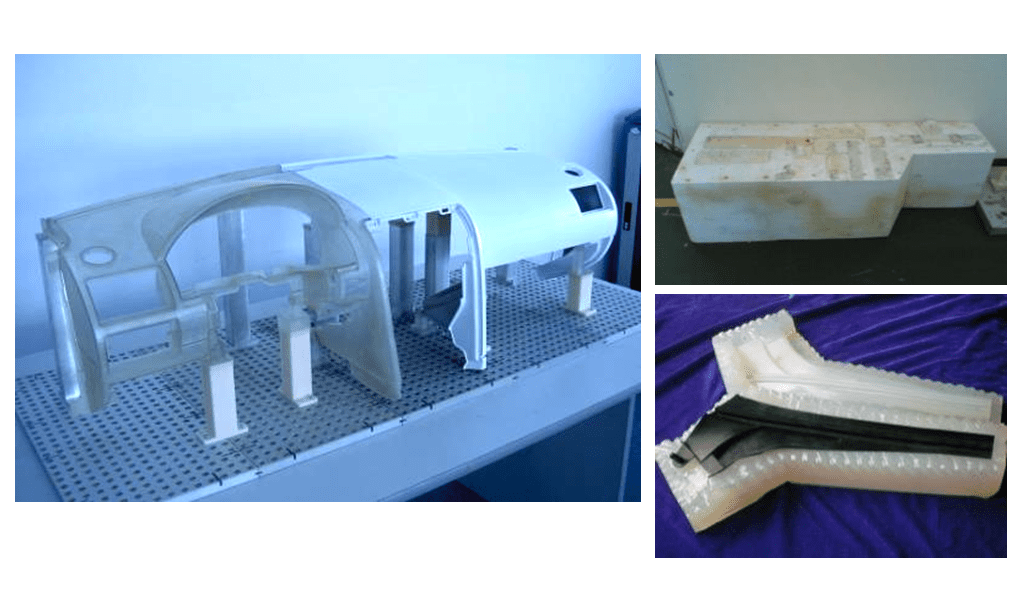

Vacuum Casting

Dangane da aikace-aikacen fasahar RP, sabon layin ha?aka samfuran, wanda yayi amfani da RTV silicon rubber gyare-gyare da gyare-gyaren vacuum, yanzu an yi amfani da shi sosai a fagen motoci, lantarki da filin likitanci.

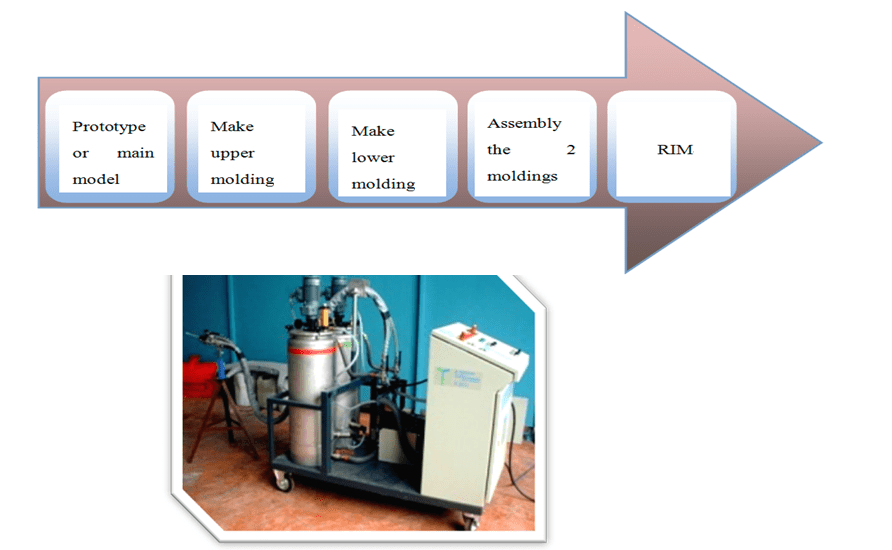

RIM: Low-matsi dauki allura gyare-gyare (Epoxy gyare-gyare)

RIM sabon tsari ne da ake amfani da shi don samar da gyare-gyaren sauri. Yana da cakuda kayan polyurethane guda biyu, wanda aka allura a cikin sauri m m karkashin al'ada zafin jiki da kuma low matsa lamba da kuma kafa ta sinadaran da kuma jiki tafiyar matakai kamar polymerization, crosslinking da solidification na kayan.

Yana da ab?buwan amf?ni na babban inganci, gajeren sake zagayowar samarwa, tsari mai sau?i da ?ananan farashi. Ya dace da ?ananan gwajin gwaji a cikin tsarin samar da samfurori, da kuma samar da ?ananan ?ira, tsari mai sau?i na murfin da kuma samar da samfurori masu kauri mai kauri da rashin daidaituwa.

m molds: guduro mold, ABS mold, aluminum gami mold

kayan simintin gyare-gyare: polyurethane mai kashi biyu

kayan jiki na zahiri: kama da PP / ABS, samfurin yana da rigakafin tsufa, juriya mai ?arfi, babban matakin dacewa, sau?in ?auka da saukewa.

Ka'idar aiki na RIM low-matsi perfusion gyare-gyaren ita ce kamar haka: kayan da aka riga aka kafa guda biyu (ko multi-bangaren) ana ciyar da albarkatun ruwa a cikin kai ta hanyar famfo mai aunawa a wani rabo, sannan a ci gaba da zuba a cikin da mold don samar da wani dauki solidification gyare-gyare. Ana samun daidaitawar rabo ta hanyar canji a cikin saurin famfo, wanda ke sarrafa adadin fitarwa na naúrar famfo da lokacin allura.

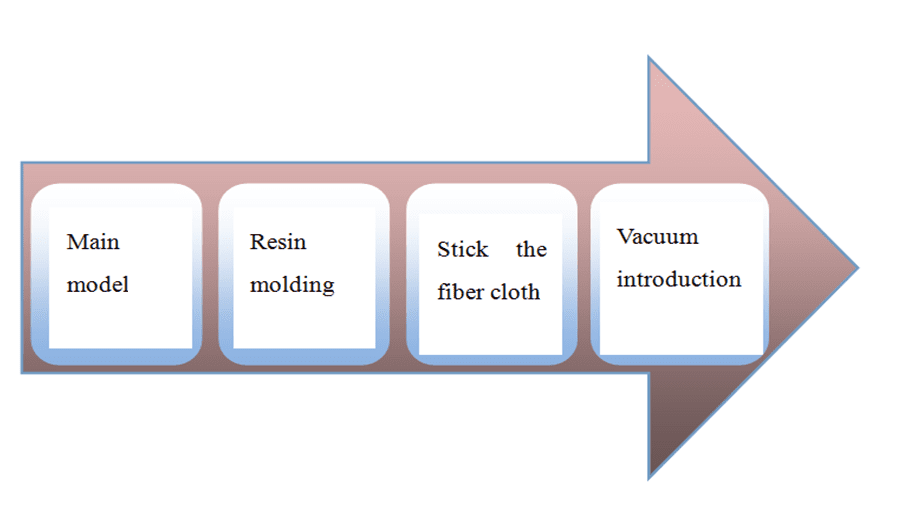

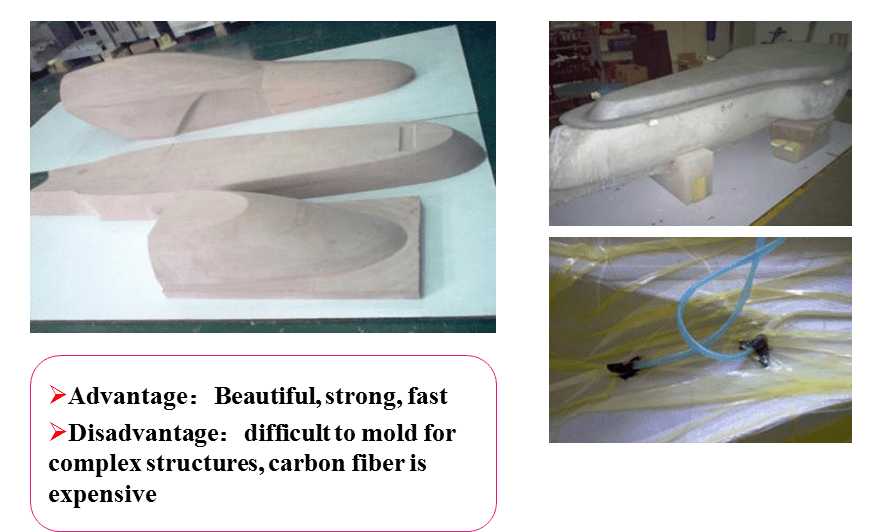

Carbon fiber / fiber ?arfafa robobi (FRP) gabatarwar injin motsa jiki

Ainihin ka'idar tsarin gabatarwar injin yana nufin shimfi?a fiber gilashi, masana'anta fiber gilashi, abubuwan da ake sakawa daban-daban, zanen saki, layin guduro mai yuwuwa, shimfida bututun guduro da suturar nailan (ko roba, akan madaidaicin gashin gel ?in da aka warke). Silicone) fim mai sassau?a (watau jakar iska), fim ?in da kewayen rami an rufe su sosai.

Ana fitar da kogon kuma ana allurar resin a cikin rami. Tsarin gyare-gyaren da aka yi wa resin ciki tare da bututun guduro da filayen fiber a ?ar?ashin injin da za a zubar da dam ?in fiber a cikin zafin jiki ko ?ar?ashin dumama.

Yin wasan kwaikwayo cikin sauri

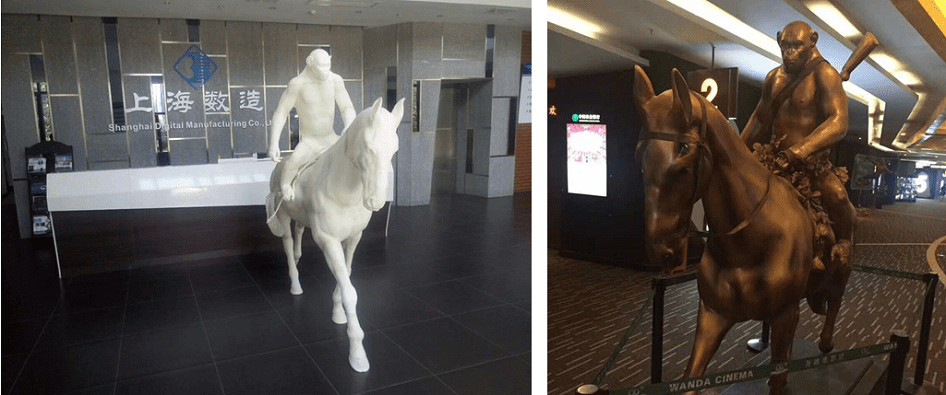

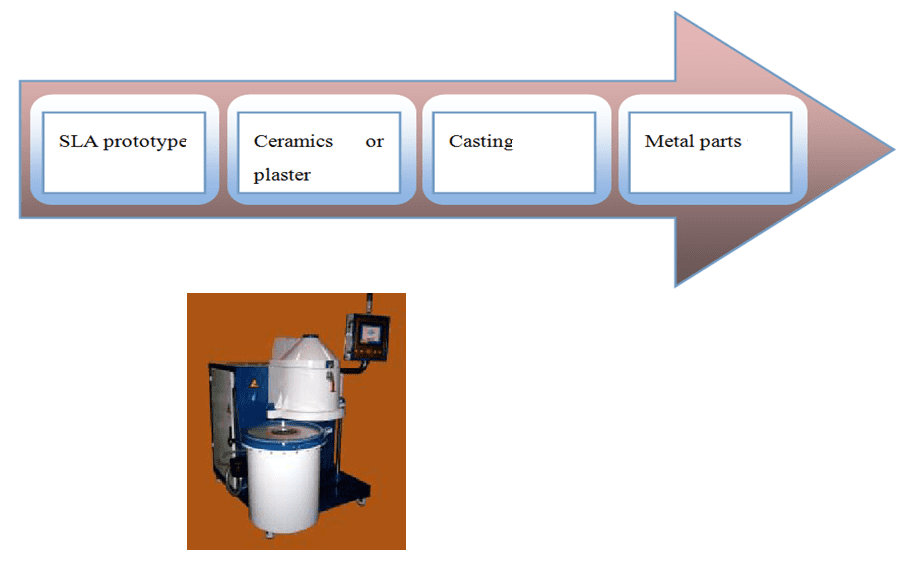

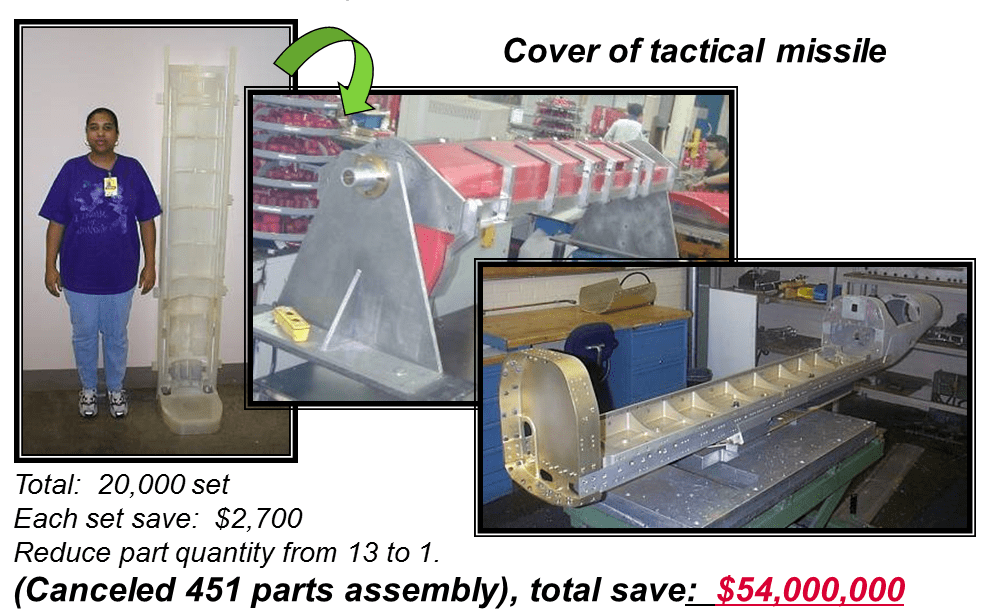

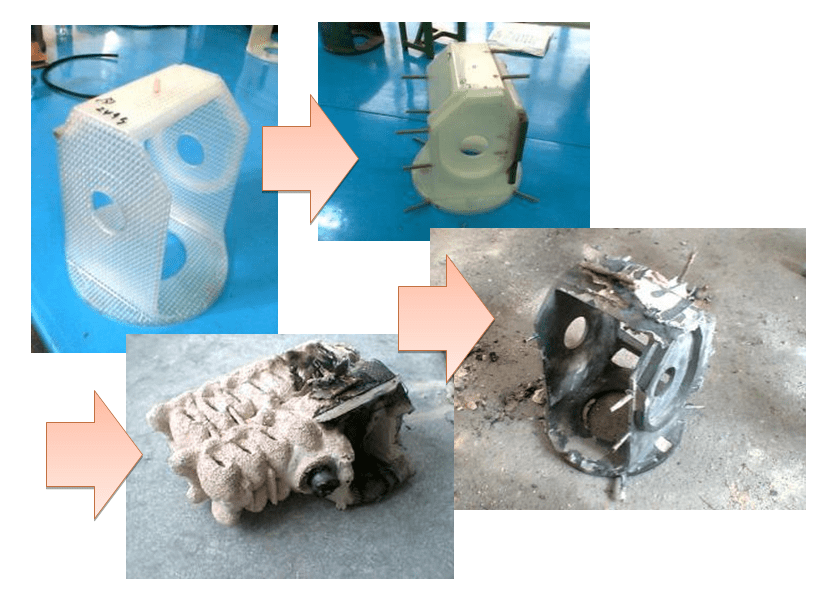

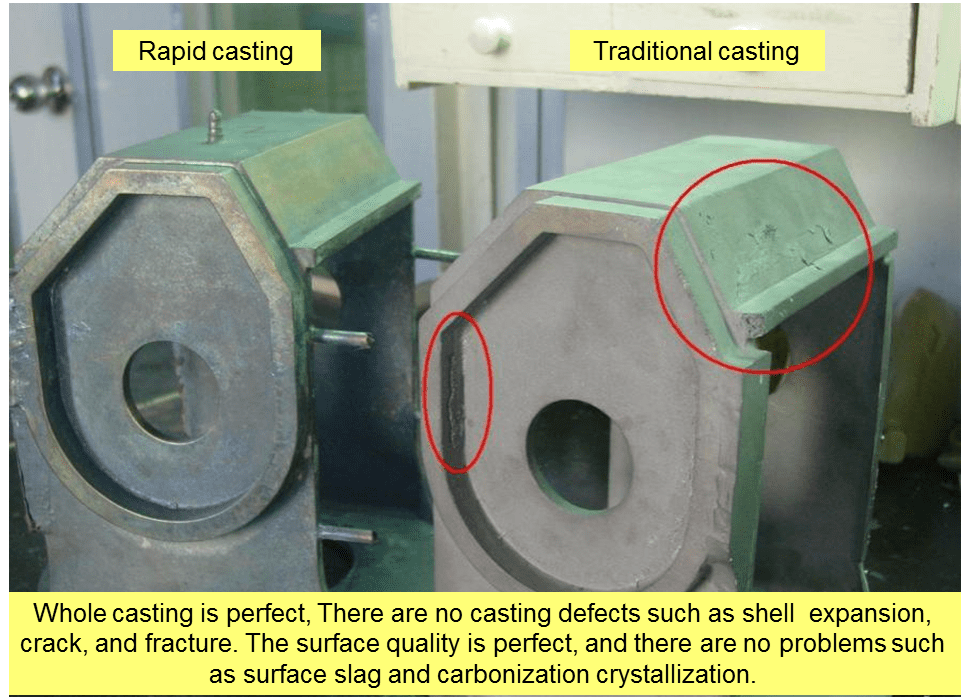

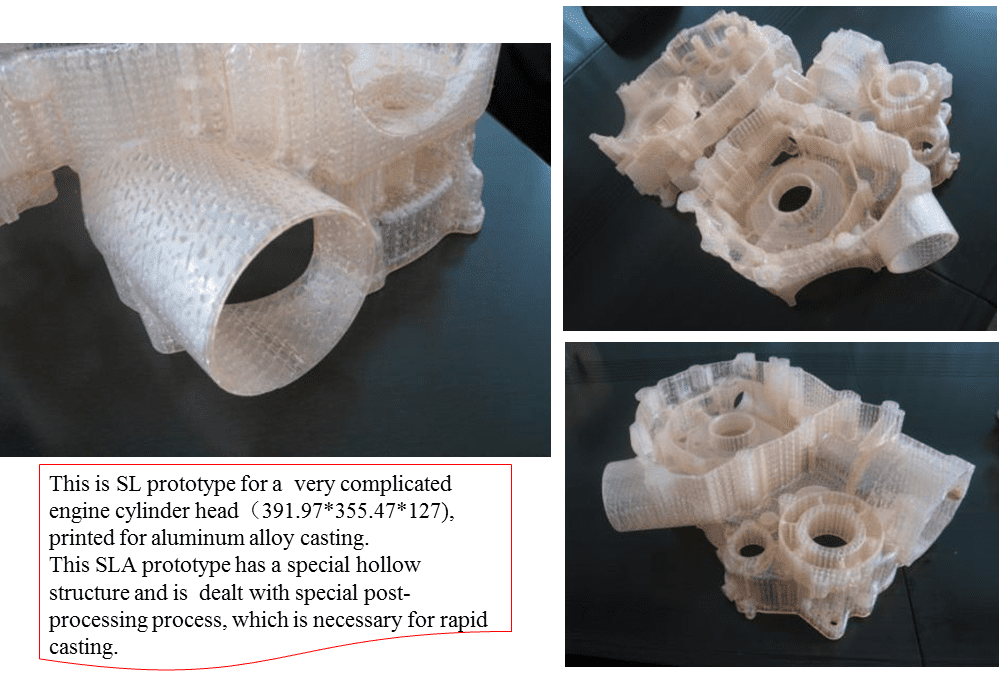

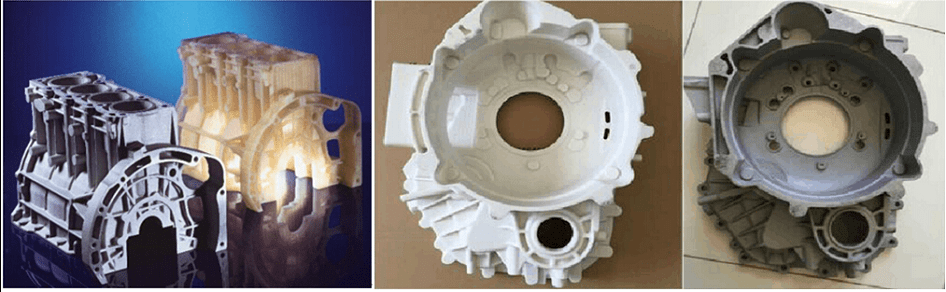

Ha?in fasahar bugu na 3D da fasahar simintin al'ada ya haifar da fasahar simintin sauri. Babban ?a'idar ita ce amfani da fasahar bugu na 3D kai tsaye ko a kaikaice buga kumfa da ta ?ace, polyethylene mold, samfurin kakin zuma, samfuri, mold, cibiya ko harsashi don yin simintin gyare-gyare, sa'an nan kuma ha?a tsarin simintin al'ada don jefa sassan ?arfe da sauri.

Ha?in fasahar bugawa na 3D da tsarin simintin gyare-gyare yana ba da cikakkiyar wasa ga fa'idodin bugu na 3D mai sauri, ?arancin farashi, ikon kera sassa masu rikitarwa da jefa kowane nau'in ?arfe, kuma ba a shafa su da siffar da girman, da ?arancin farashi. Ana iya amfani da ha?in ha?in su don kauce wa rauni, sau?a?awa sosai da rage tsarin tsari mai tsawo, gyare-gyare, sake tsarawa zuwa gyare-gyare.

Zuba jari

Yin simintin saka hannun jari yana nufin sabon hanyar simintin ?arfe, wanda kuma aka sani da cikakken mold, vaporization, da simintin ?orafi. An yi samfurin da kumfa (FOAMED PLASTIC) kuma yawanci ana fa?a?a polystyrene. Madaidaicin ?irar yana cike da yashin simintin gyare-gyare (FOVNDRY SAND) don samar da mold (MOLD), kuma haka yake ga mummunan mold. Lokacin da aka ?ora narkakken ?arfen a cikin gyaggyarawa (watau ?irar da aka yi da polystyrene), kumfa ?in ya ?ace ko ya ?ace, yana barin mummunan yashi na yashi mai cike da narkakkar karfe. Wannan hanyar yin simintin gyare-gyaren da aka yi amfani da ita daga baya ne ta hanyar masana'antun masana'antu.

An ba da shawarar firinta SL 3D

Ana ba da shawarar babban girman firinta na SL 3D, kamar 3DSL-600Hi tare da ?arar ginin 600 *600*400 mm da babban injin 3DSL-800Hi tare da ?arar ginin 800*600*550mm.